In addition to our precision machining facilities and expert staff members, Hongsinn has a proven track record of achieving successful outcomes for our customers, regardless of company size or industry. Quality is one of the most essential factors for purchasers around the world and the quality of the goods that leave our factory demonstrates our commitment to excellence.

Hongsinn implements quality control measures in every procedure from materials purchasing, through production, and finished inspection. Our highly experienced and expert staff will inspect all parts, making sure they’ve met all the requirements, including the dimensions and tolerance provided by our clients.

Material TestingSample testing will be completed by material testers as soon as the materials are delivered to the production facility. The purpose is to ensure the material can fulfill the needs of our clients. If they do, we will then provide certification.

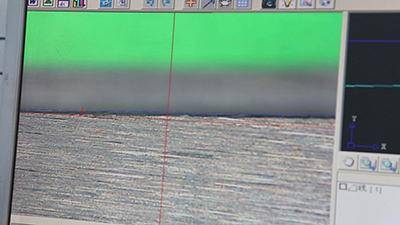

Two and a half dimensional imagerWe use it to measure dimensions that are not easily seen like radius and angles of the parts.

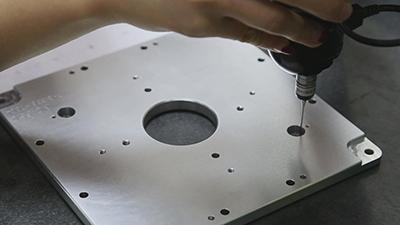

Height gaugeOur quality staff can maintain the precision of 0.01mm when using the height gauge for the inspection.

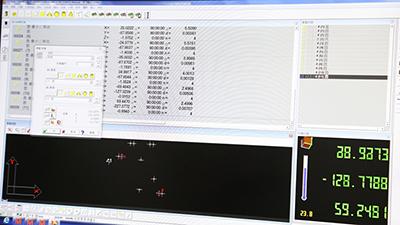

Mitutoyo Coordinate Measuring MachinesWe are able to gather data by measuring the tolerance on size, shape, location and sculpted surfaces with the precision of 1 micron.

KEYENCE (Optical Comparators)The efficiency has been improved as this machine can test 99 finished products simultaneously.

Hardness TesterThe hardness will be inspected to find out whether it is consistent with what is required.

Request a Quote? Feel free to contact us at any time!

Click