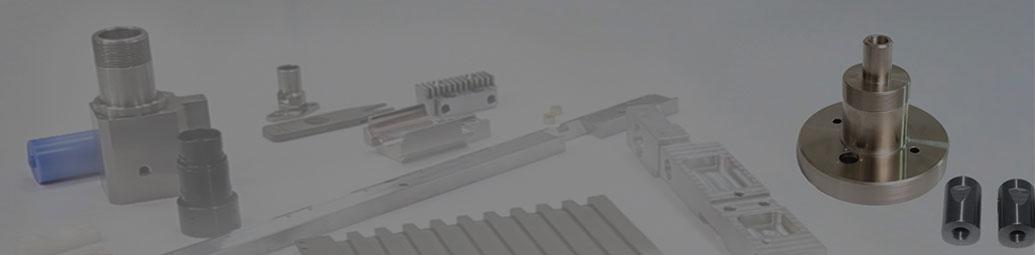

Are you looking for a full-service provider for machine components processing? Look no further than Hongsinn. We are a Shenzhen based precision machining services provider, offering a wide array of custom machining services for manufacturing industries, including automotive and medical.

What are the advantages of CNC precision machining?Computer numeric control (CNC) machining is a process that automates machine tool operation via perfectly programmed computer commands. CNC machining is commonly divided into two categories: CNC milling and CNC turning, and is a popular method for precision machined product manufacturing. CNC precision machining produces a wide array of complex parts and components with an exceptionally high accuracy. Lathes, grinders, routers, and mills are all machines and tools capable of being CNC controlled.

SpecsMinimum size: 0.5-1mm*0.5-1mm

Maximum size: 2m*2m

Accuracy: 0.01mm

-

Services

We use CNC turning and CNC milling during production that is ideally suited to the production of intricate parts where precision and accuracy are required.It doesn’t matter how small, large, or complex you need your machining parts, please do not hesitate to contact us for more information or assistance. Hongsinn is outfitted with an experienced, expert staff to meet every need and specification, including complex shapes and multiple surface treatment types.

-

Materials

Plastic and metal materials are both available, as we work with qualified suppliers who provide an extensive array of materials, including raw materials imported from Japan. We also carry out material analysis and offer our customers a composition report upon request.

-

Quality

Quality is always a top priority. We carry out an inspection of every production step and every finished product to ensure anything that leaves our facilities meets the highest industry quality standards.

Request a Quote? Feel free to contact us at any time!

Click